EP1001

Molding and Casting\

Molding

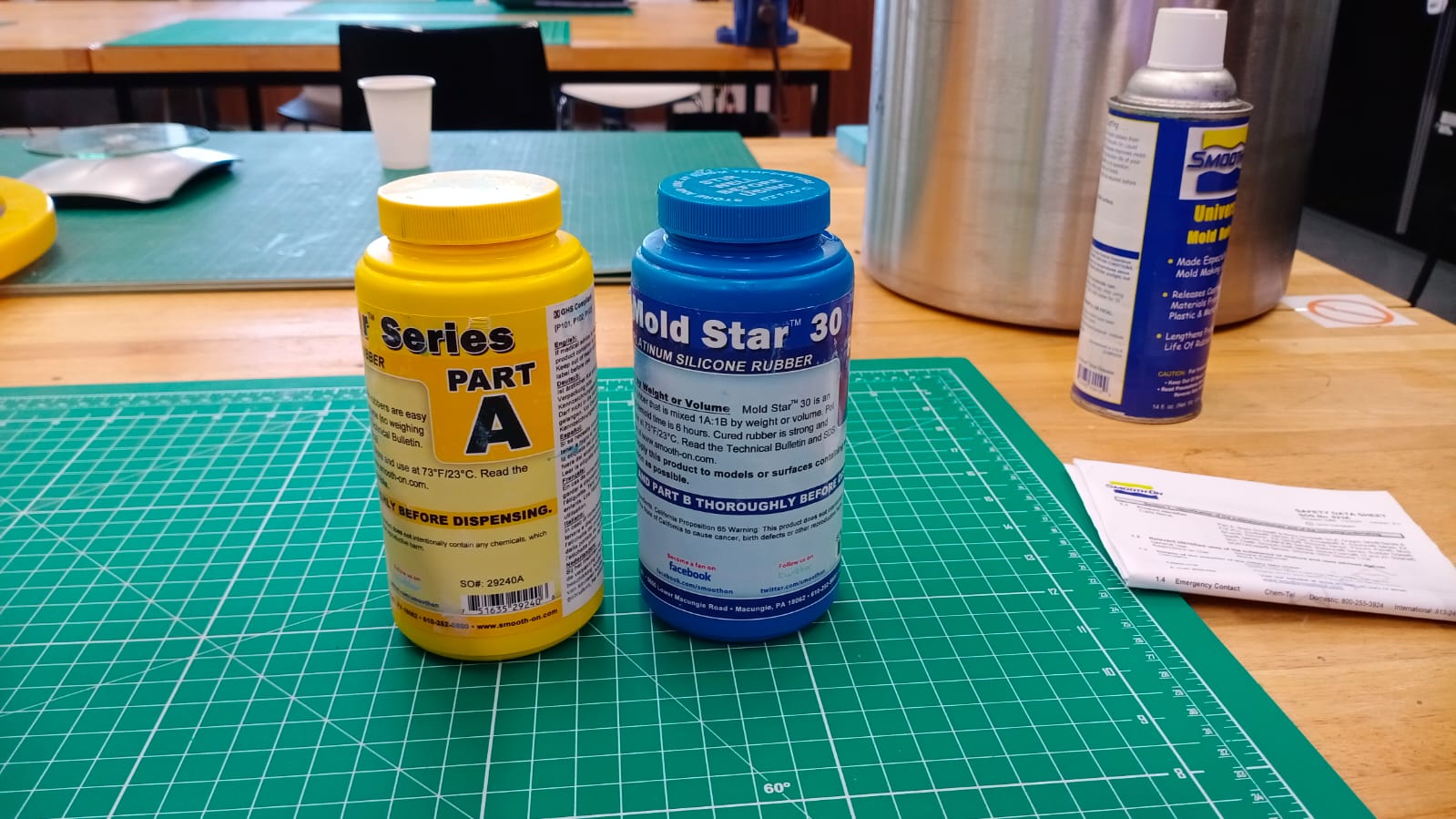

First, I will do molding for the mold model. I used the Mold Star Silicone Rubber. There are 2 bottles labeled A and B. The ratio for molding is 1:1.

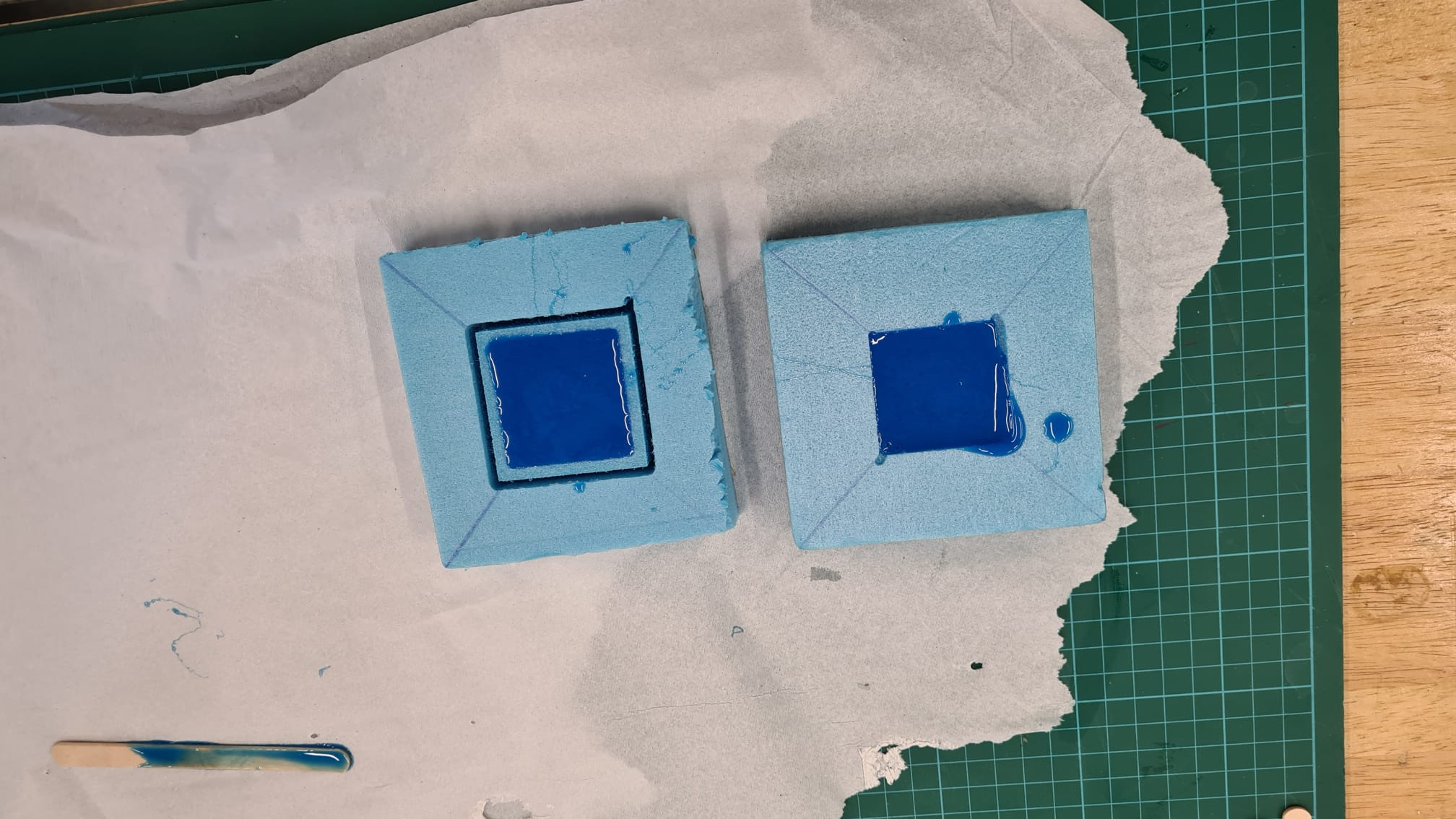

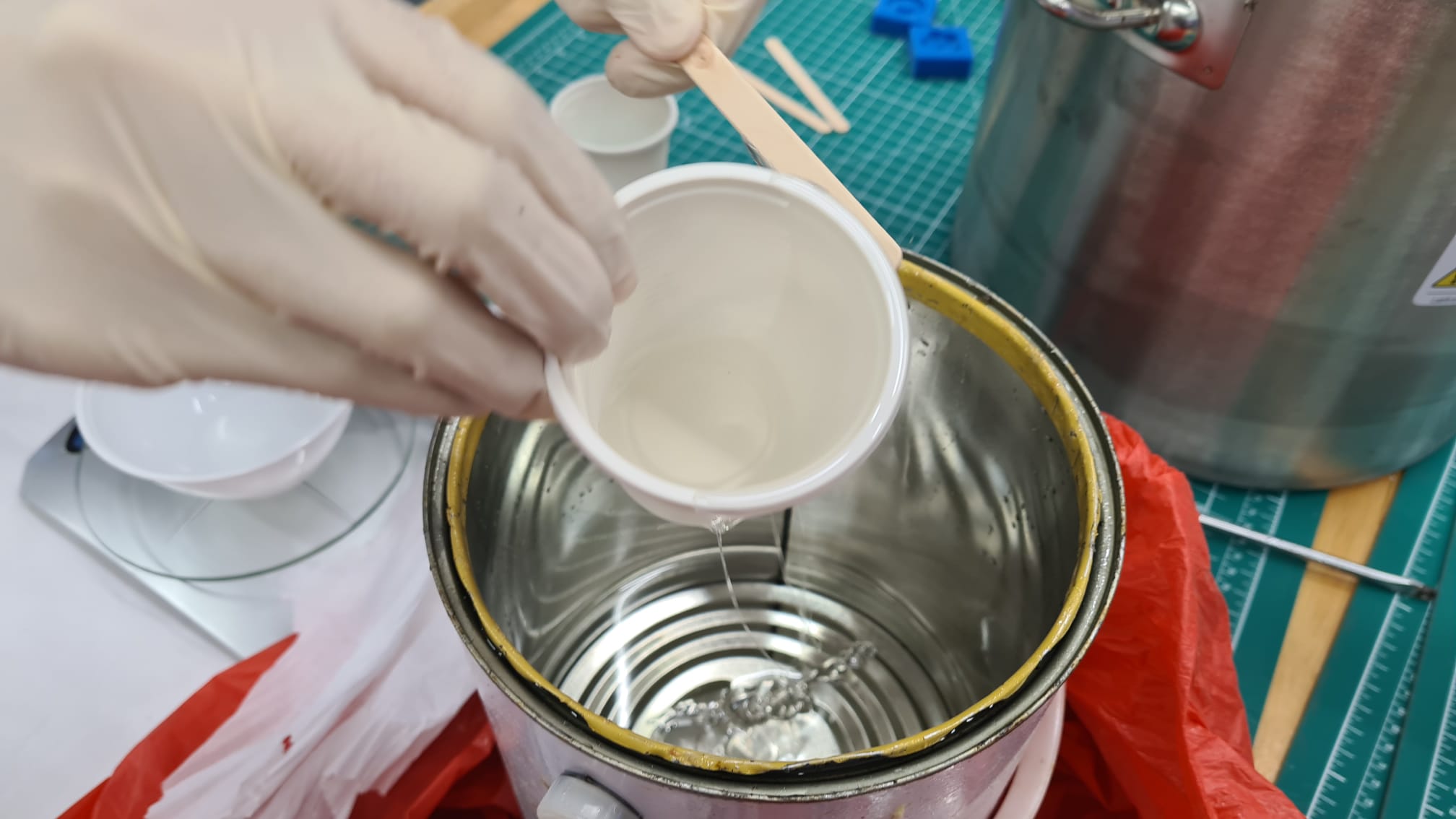

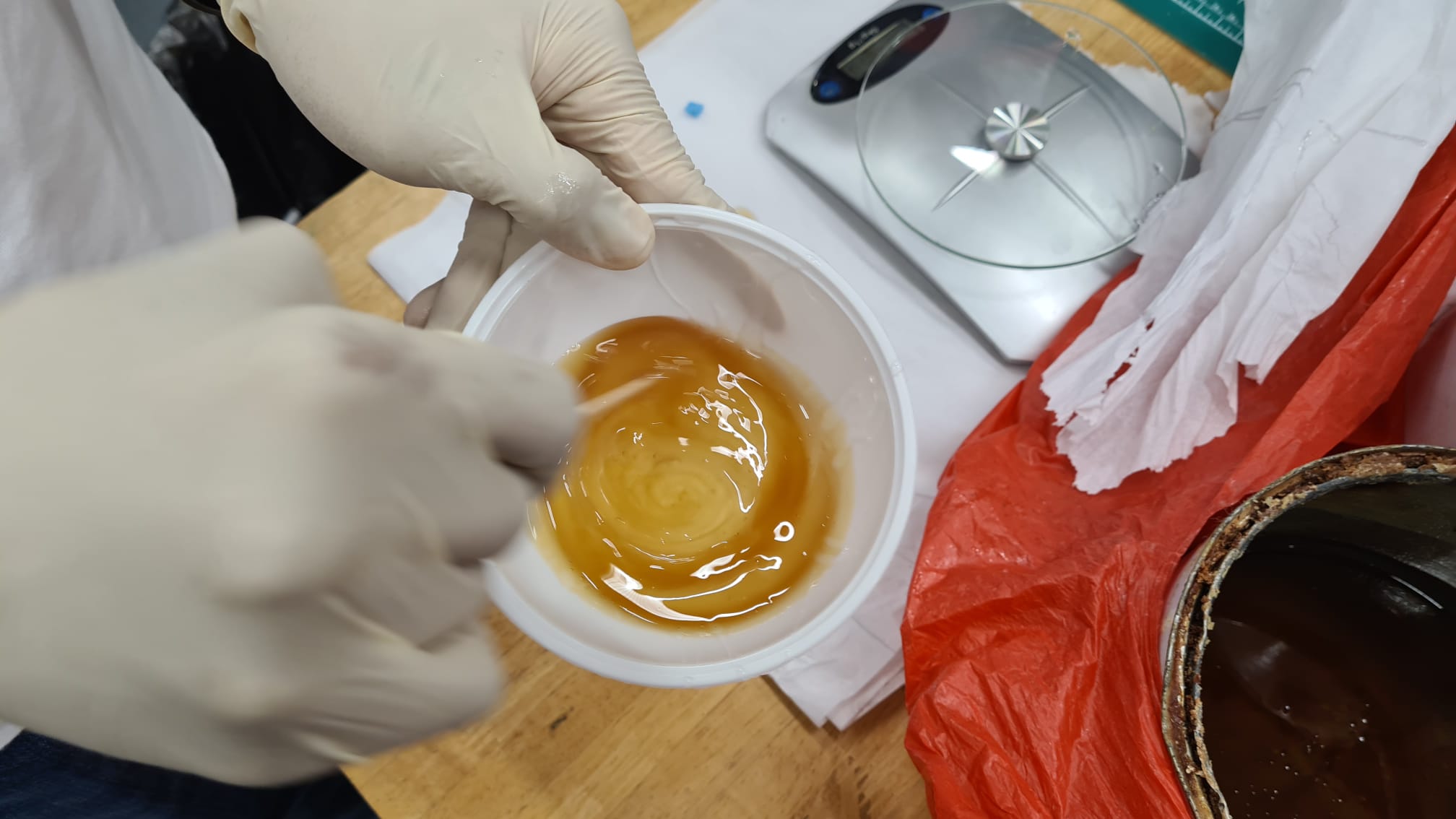

Before starting, I need to cover the workspace with tissue as it gets messy. I also need to wear plastic gloves. Please use the correct gloves as the compund may react to the gloves. Then I poured the compunds into a plastic cup. Since I’m doing the mold together with a friend, we used 50g each of A and B.

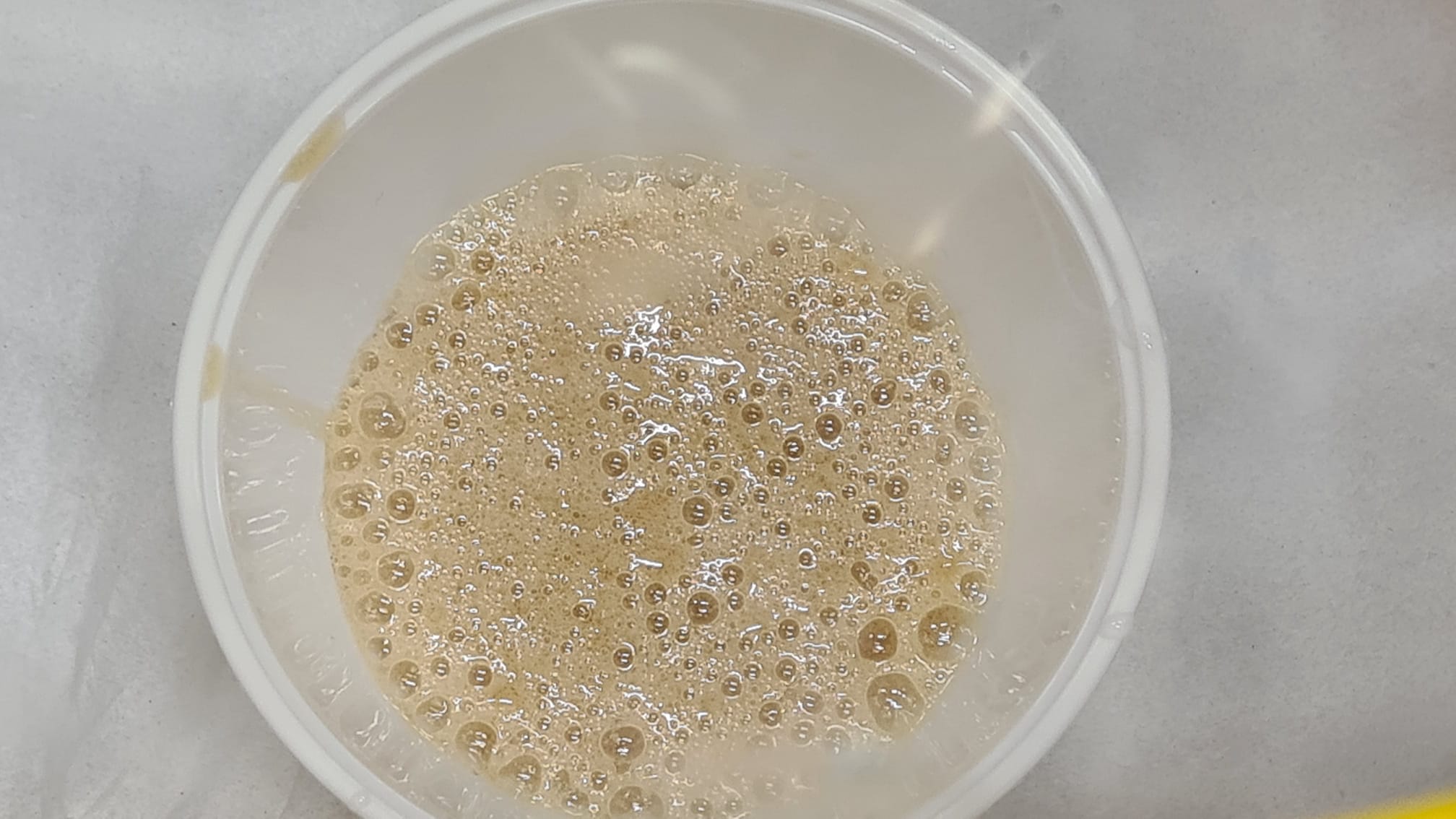

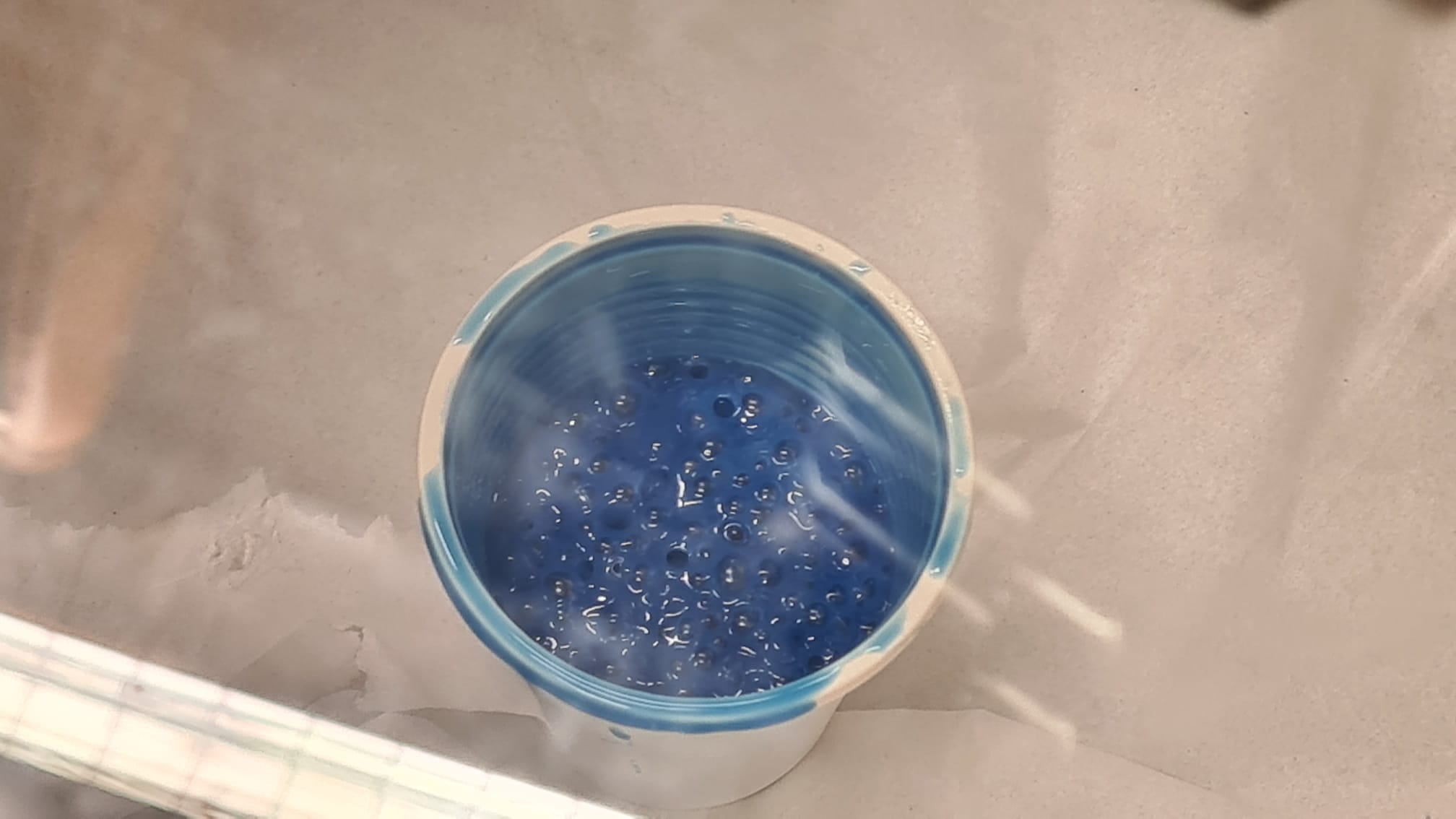

After that, I mixed the compounds well before putting it in the vacuum chamber. This will remove any bubbles in the compound, ensuring that the mold surface would be smooth.

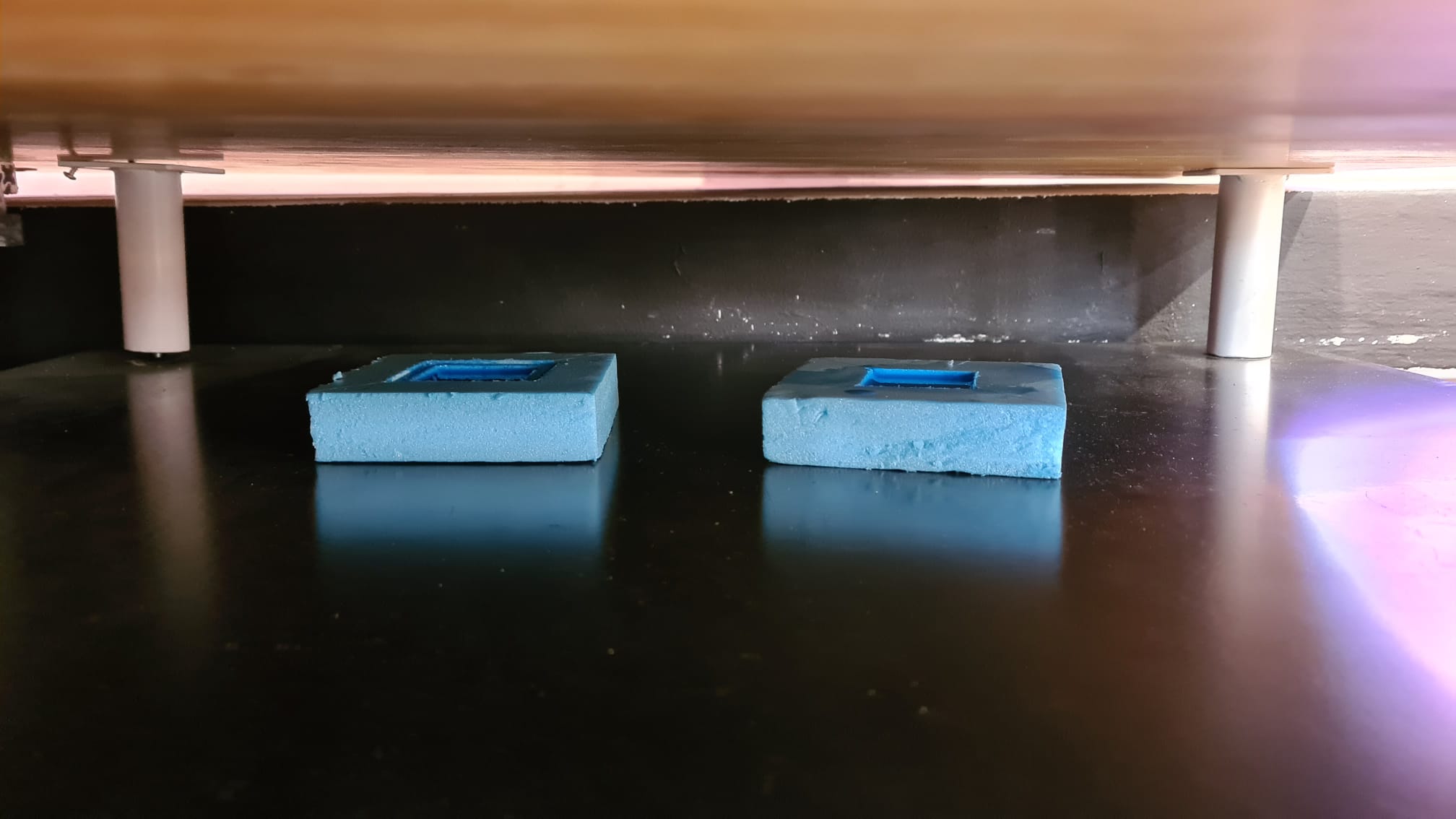

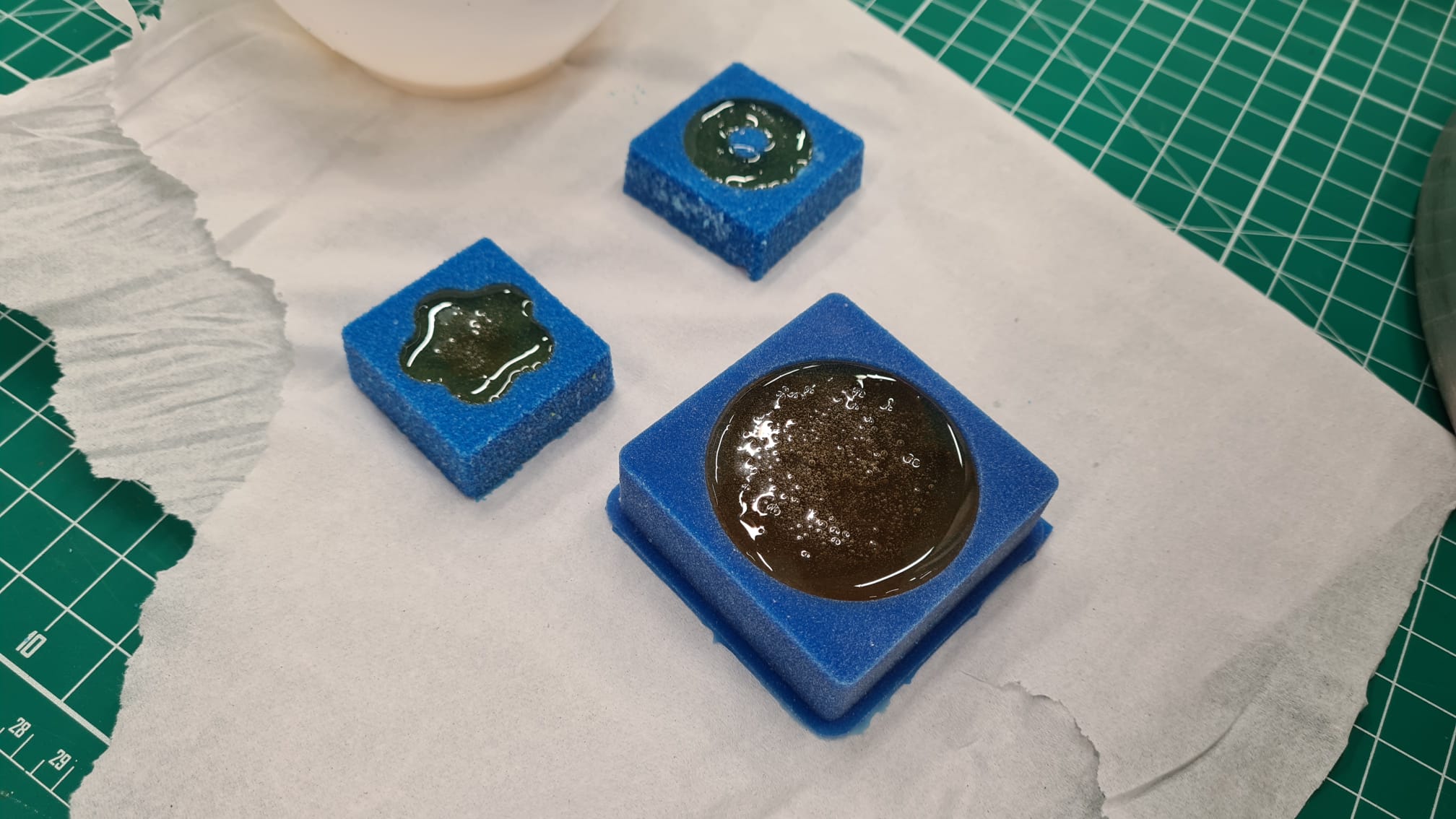

After degassing, I poured the compound into the mold. Ensure that the entire mold is filled. The instructions stated that the curing takes up to 4hrs but I decided to leave it overnight to ensure maximum curing.

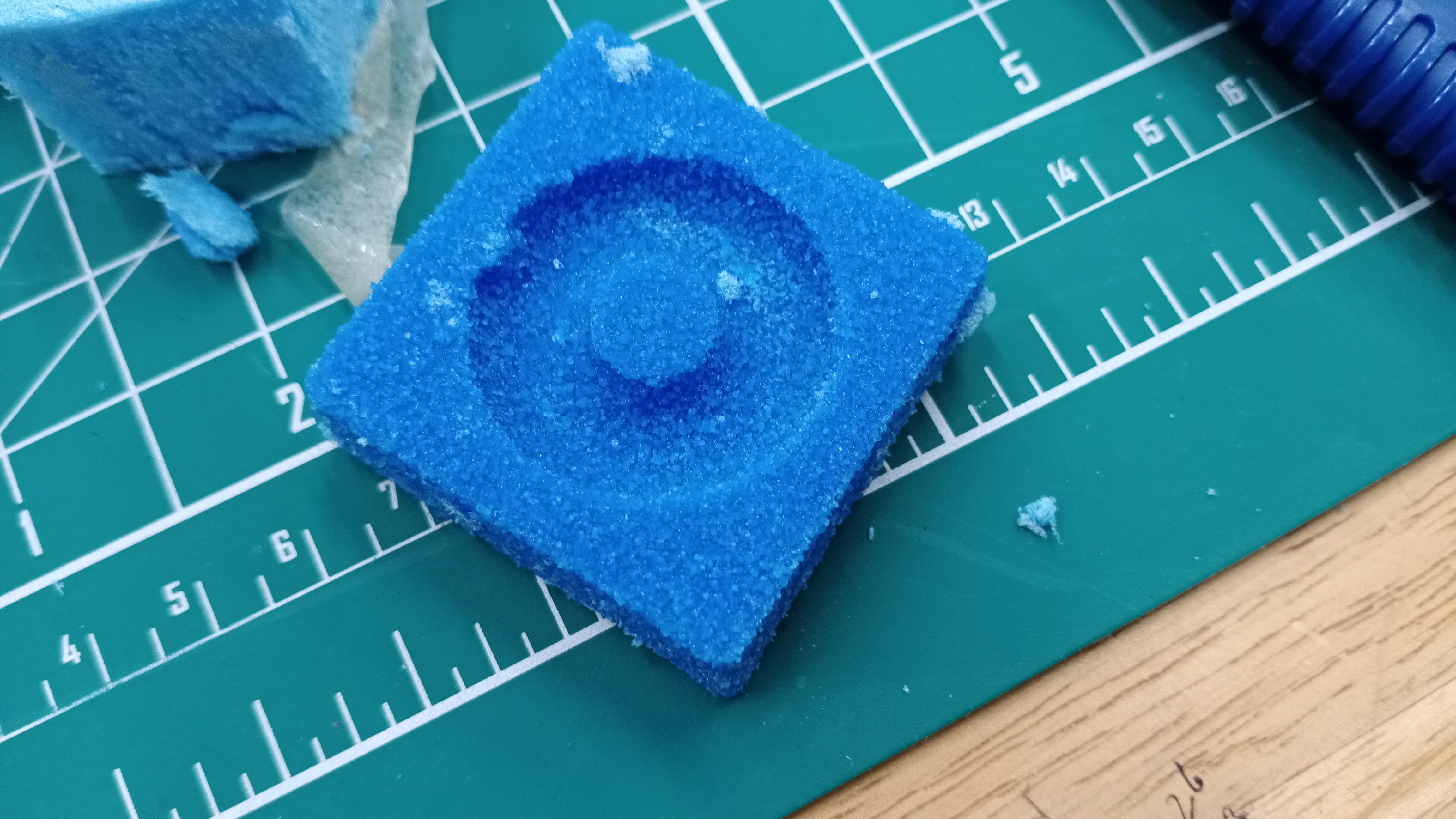

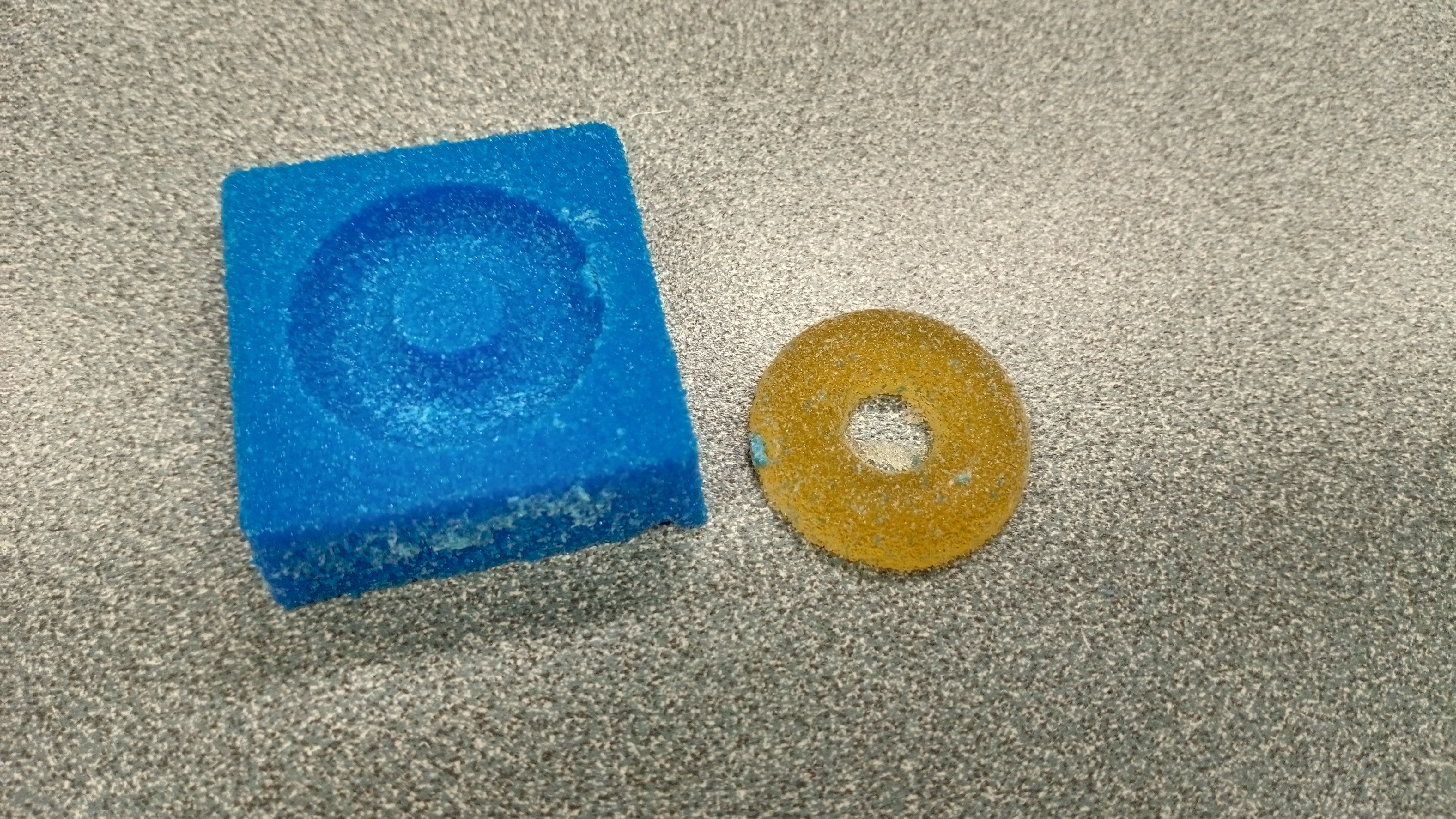

The mold looks alright. the surface felt grainy, this could be due to the resin used. I used the Mold Star 30 so I think I would be able to obtain better finishing if I used the Mold Star 300.

Casting

Next up is time for casting. The process for casting is basically the same as molding. The only difference is that we are using resin-hardener set instead of silicone rubber. The ratio for resin-hardener is 3:1. Compared to molding, this set is quite messy to work with. The pot life after mixing is about 10 mins so we got to work fast.

Just like molding:

- Pour the amount needed for each compound into a cup

- Mix well

- Degas the mixture

- Pour into mold

- Let it cure. I let it cure overnight for maximum performance

Overall the cast came out alright. The surface was quite grainy, this is due to the surface finish of the mold.

.jpeg)

.jpeg)

.jpeg)

.jpeg)